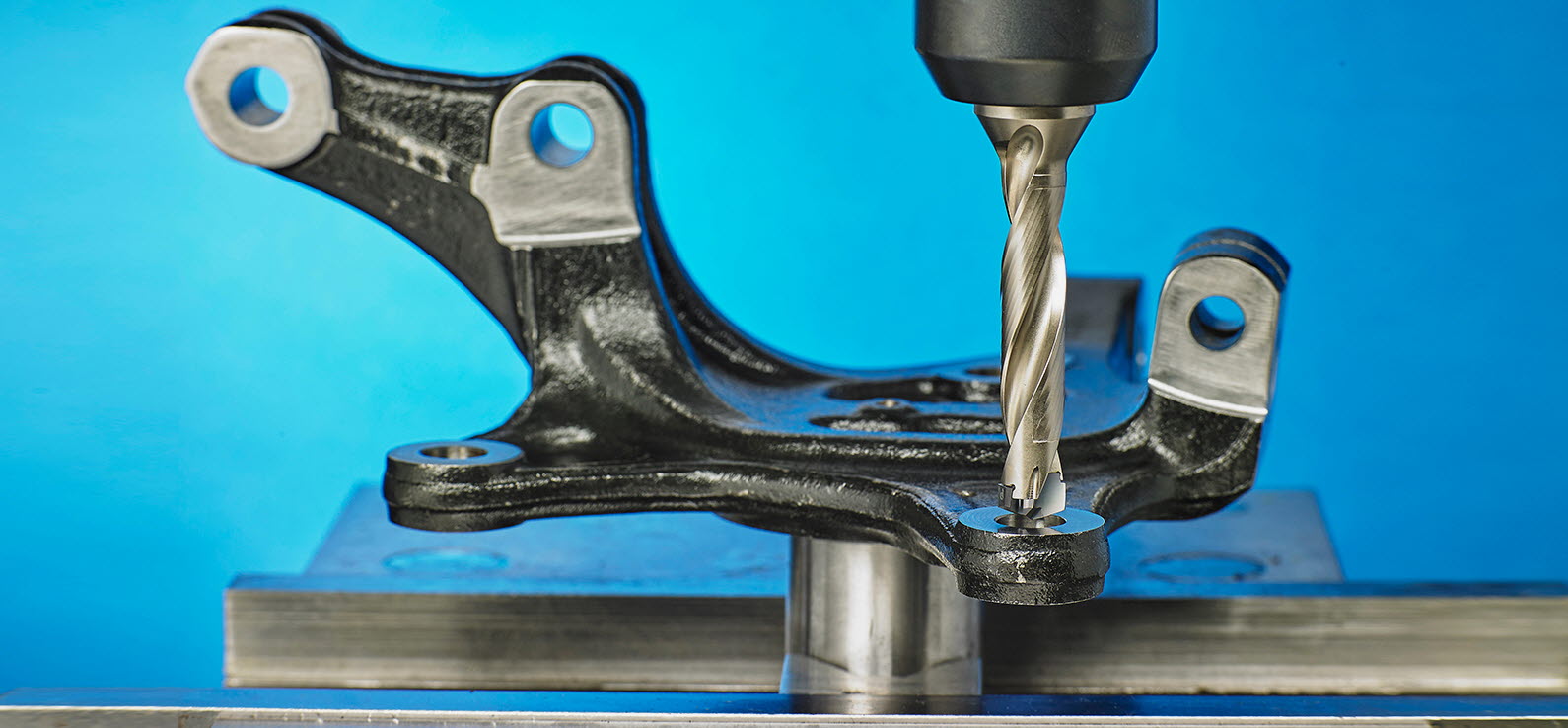

– High precision drilling available to the level of carbide solid drill

• High feed

– High feed machining available through stable chip evacuation with optimized cutting edge & helical oil hole

TPDC

As for existing indexable drills for general purpose, there was problem with low productivity and poor machining precision due to chip shape and poor chip evacuation when machining tough material such as mild steel and forged steel.

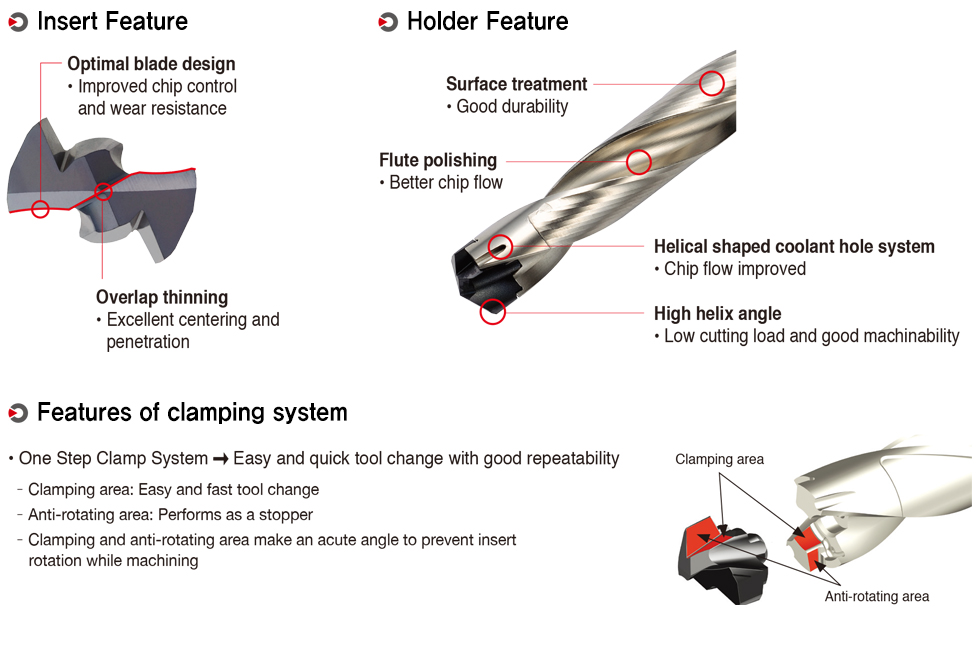

In order to solve this problem, blade design and coolant hole system has upgraded to make it possible to get good chip geometry and stable chip flow in any material of workpieces. As a result, productivity has been improved than that of previous indexable drills for general purpose, with availability in high speed and high feed machining.

On top of that, the One step clamp system applied to TPDC for easy and quick tool change. This clamping design allows to change inserts while the holder is attached on the machine in a shortened setting time. Better stability and sustainability are now possible with this system.

TPDC inserts guarantee excellent anti chipping and wear resistance by ultra fine substrate and multi layer coating. Not only that, special surface treatment on the holders improves durability and chip flow.

Advantages

• One step clamp system

– Rigidity and stability

• Easy to change inserts

– Shortened setting time

• Optimized blade design

– Excellent chip control

• Helical shaped coolant hole system

– Better chip evacuation

• Material technology

– Excellent anti chipping & wear resistance