Feature

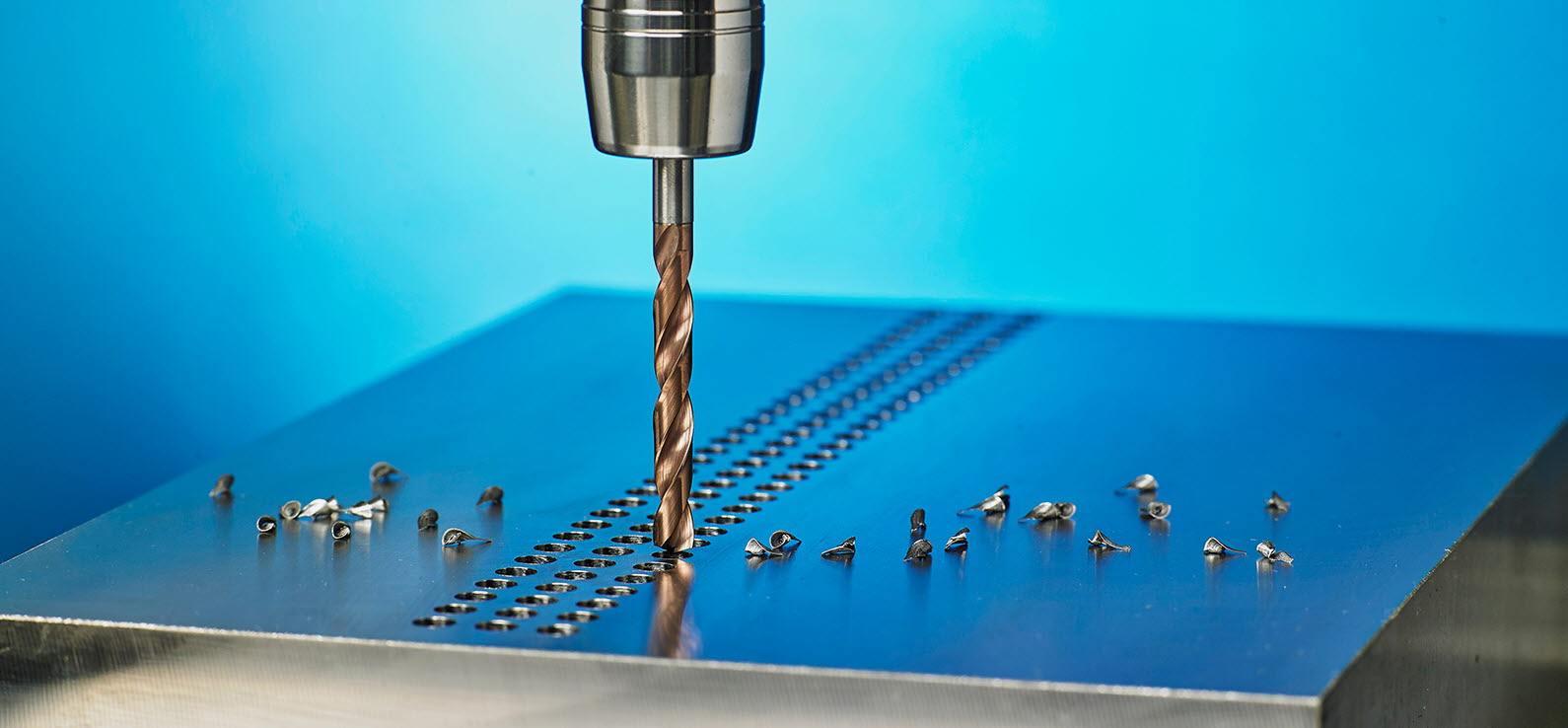

• Improved chip evacuation

– Excellent chip evacuation thanks to wider chip pockets.

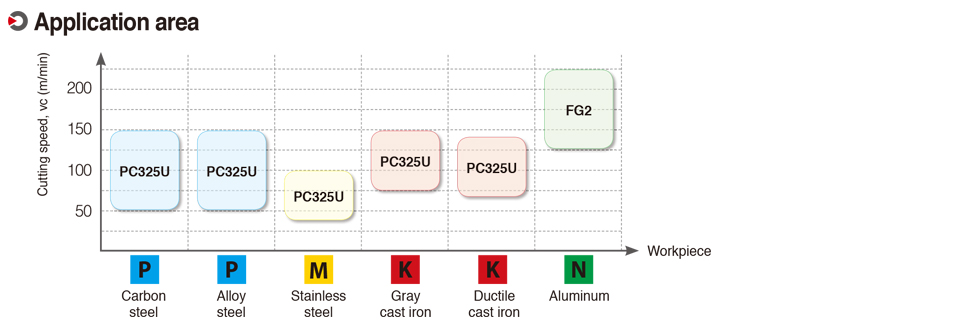

• Increased wear resistance

– Strong wear resistance thanks to our new PC325U grade

MSD Plus

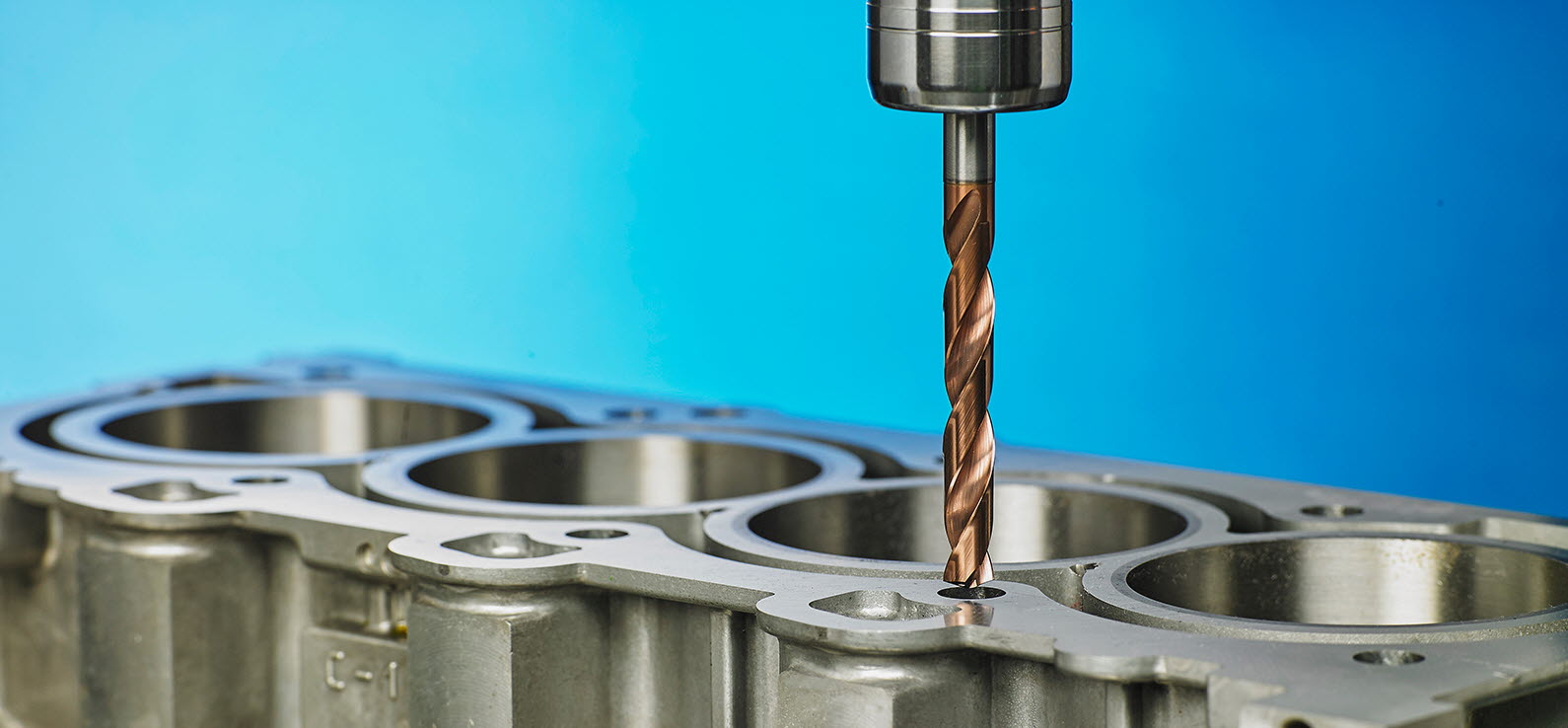

Hole making is a common operation in the cutting tool industry. Those operations are realized under various drilling conditions such as high speed, high feed, dry/wet, etc. At the same time, a wide range of workpieces like carbon steel, cast iron, alloy steel and more are being used.

In order to fulfill all the requirements of modern machining, stability and longer tool life are highly valued.

MSD Plus is a solid drill designed for high efficiency and high performance with excellent stability. Chip pockets were widened for better chip evacuation, which led to stable machining and extended tool life.

The new grade PC325U was also applied for better surface lubrication and lower cutting load, which also improved wear resistance and welding resistance. This is why MSD Plus has longer tool life and stability when machining a comprehensive range of workpieces at low speed to high speed.

Advantages

• Stable tool life

– Stable productivity

• Longer tool life

– Increased productivity

• Excellent chip evacuation

– High quality products

• Possible to machine various automobile components

– Universal to change of grades