– Excellent performance and cost efficiency

• Increased wear resistance

– Strong wear resistance due to our new PC325U grade

ESD Plus

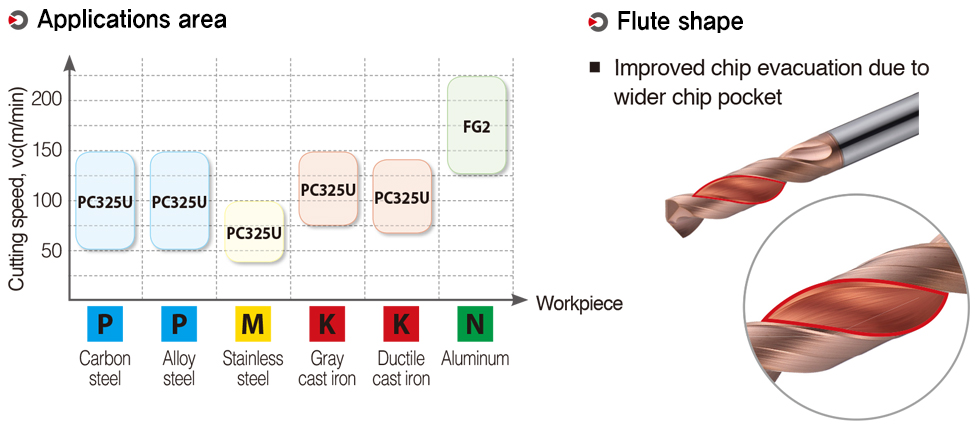

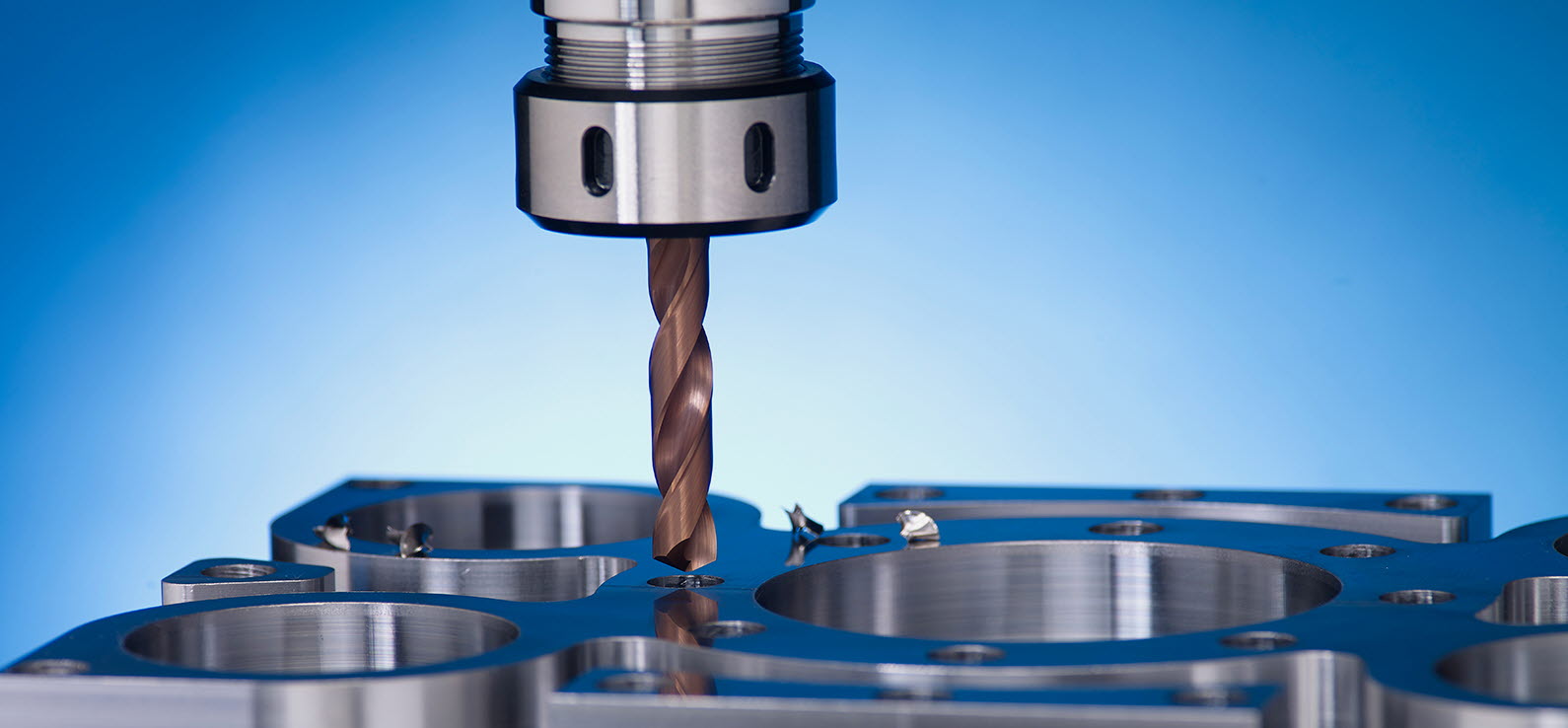

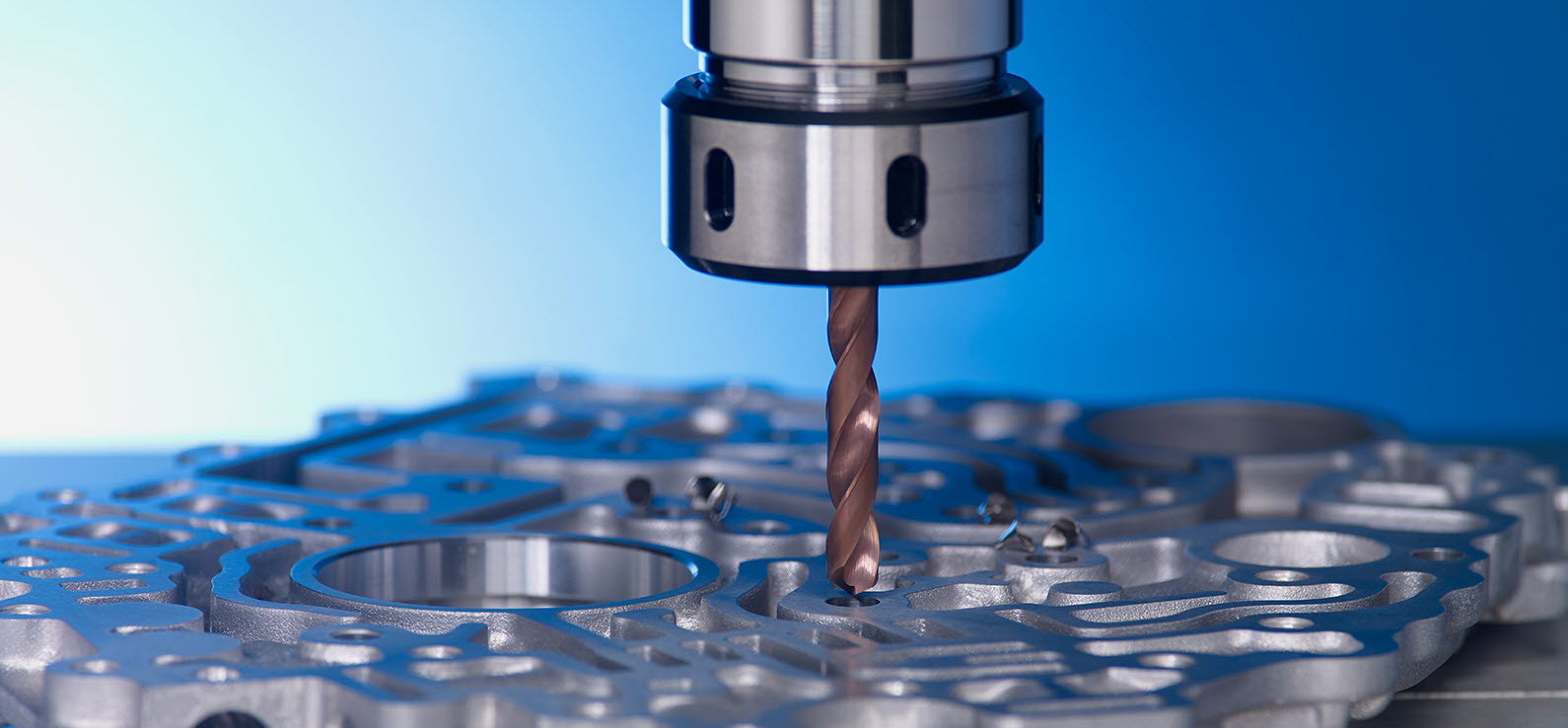

Drilling is now used not only for automotive parts but also extensively across all industries including the IT field. There are various applications in drilling, from high speed and feed machining to dry or wet. In addition, a variety of workpiece materials such as carbon steel, cast iron and alloy steel are being used, which makes excellent tool life and stable machining more important.

ESD Plus is a highly efficient solid drill with increased stability and excellent performance. Wider chip pockets have produced significantly improved chip evacuation, leading to higher machinability and longer tool life. Now with the ESD Plus, high quality industrial products can be achieved with ease.

Newly applied PC325U coating improves the surface lubricity compared to existing products, reducing the cutting load. It additionally features stronger resistance to wear and built-up edges, which extends the tool life. Furthermore, it provides stable and excellent performance in wide applications from low to high speeds, enabling various product processing.

Advantages

• Stable tool life

– Stable productivity

• Longer tool life

– Reduced tool costs

• Excellent chip evacuation

– Increased productivity

• Possible to machine various automobile components

– Versatile for a wide range of materials