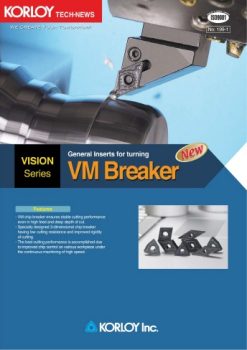

Feature

– Reduced cutting load brings stable tool life with the use of sharp cutting edges

• Stable chip control

– Increased productivity with stable chip control at varying cutting conditions and uneven surfaces

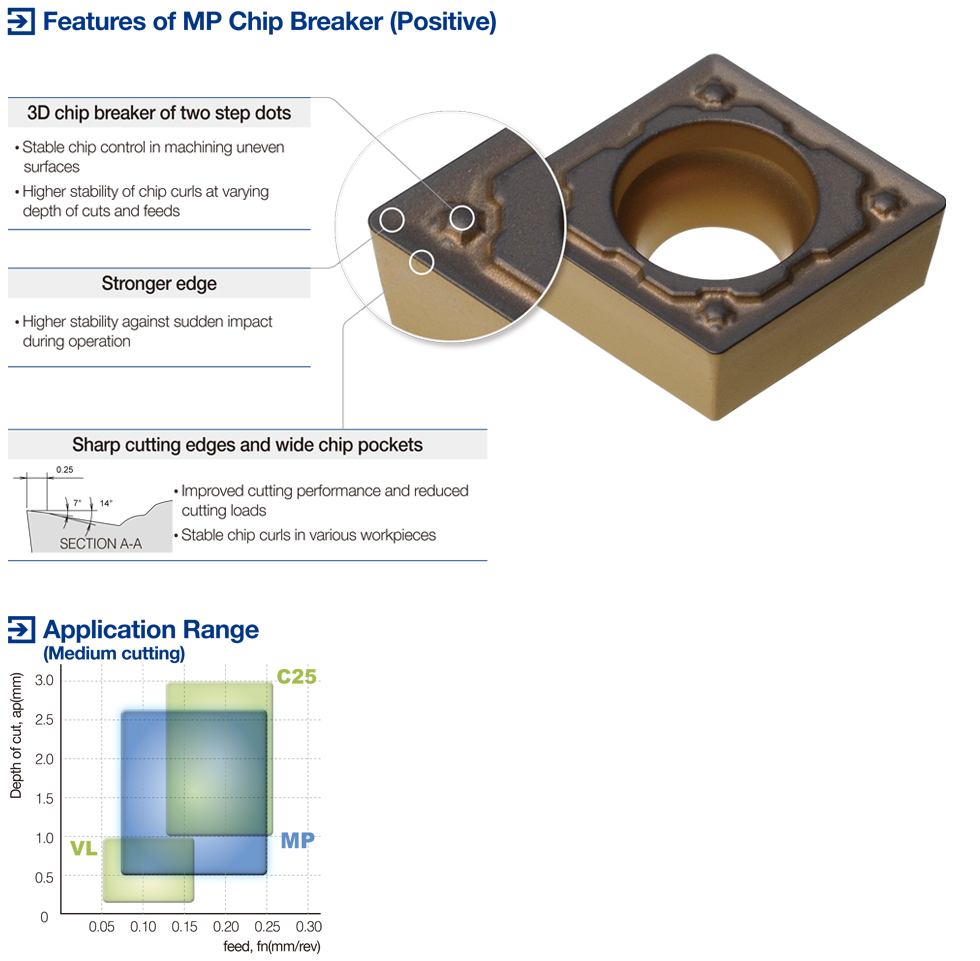

MP Chip Breaker (Positive)

The surface of forged steel that is commonly used for automobile parts is hard and tough while the inside is soft. Bearing steels also have the same characteristics of high toughness and hardness. Machining these kinds of steel repeatedly causes built-up edge and edge chipping, which is one of the main causes of reduced productivity and unstable tool life. Mass production of automobile parts requires faster cutting speeds, higher feeds, and much longer tool life than ever before.

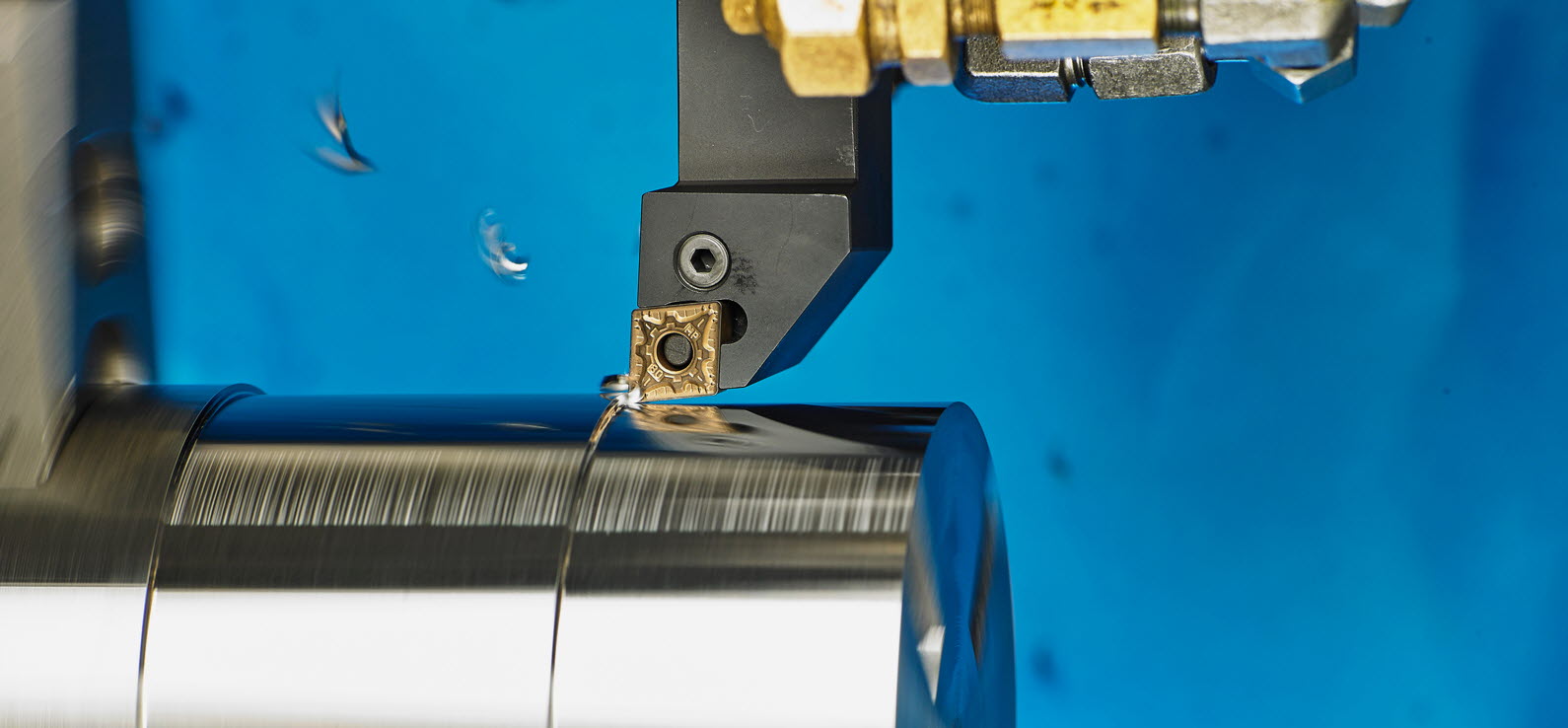

KORLOY has recently released a new ISO single-sided MP chip breaker that shows excellent performance in internal machining of automobile components. It provides stable chip evacuation and tool life by the use of insert geometries specialized for machining forged steel, bearing steel, etc. The MP chip breaker is the best solution for automobile components as well as general machine components.

The single-sided MP chip breaker reduces cutting loads due to sharp cutting edges and wide chip pockets when machining outer surface of hardened materials such as forged steel. Its special three dimensional geometries enables smooth chip evacuation by producing good chip curls even on rugged surfaces.

In addition, it largely contributes to increased productivity with the expectation of stable tool life and excellent surface finish.

Advantages

• Stable chip evacuation

– Prevents chip blocking in internal machining

• Excellent surface finish

– High quality result

• Longer tool life & High removal rate

– Makes cutting conditions higher, faster and shortens cutting time

• Applicable to various automobile components with forged steel, bearing steel, etc.

– Flexible to change of workpiece materials