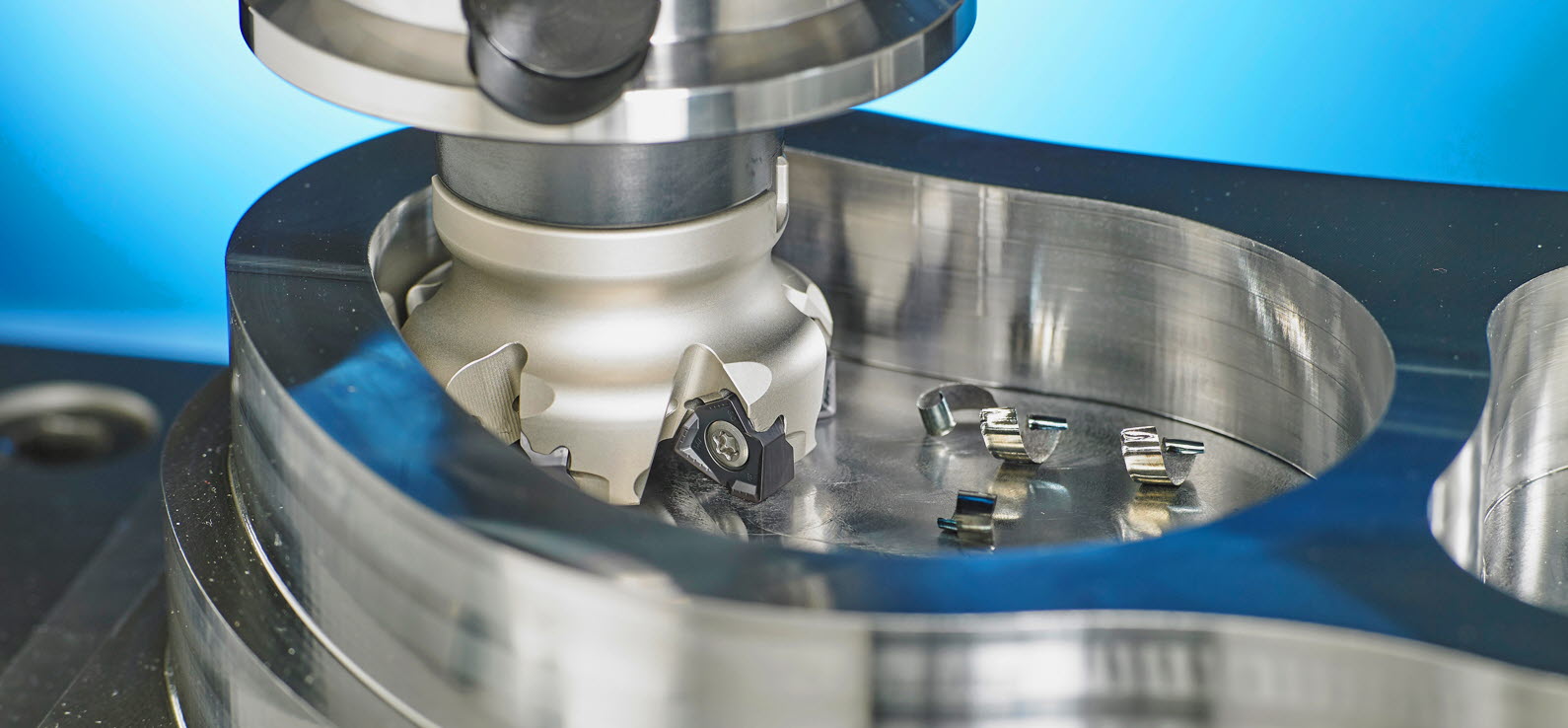

– Designed to provide high speed and feed improves chip removal rates

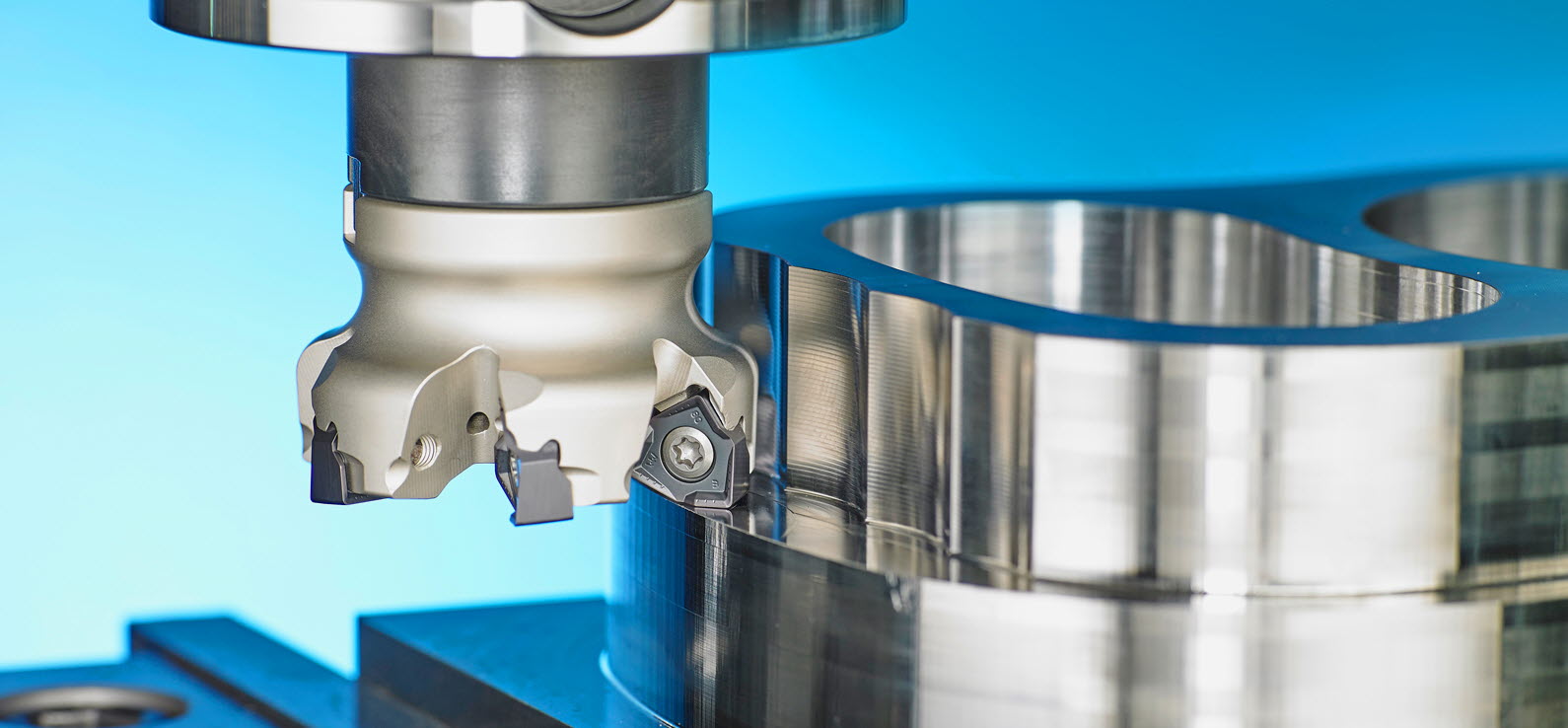

• Improved perpendicularity

– True perpendicular milling

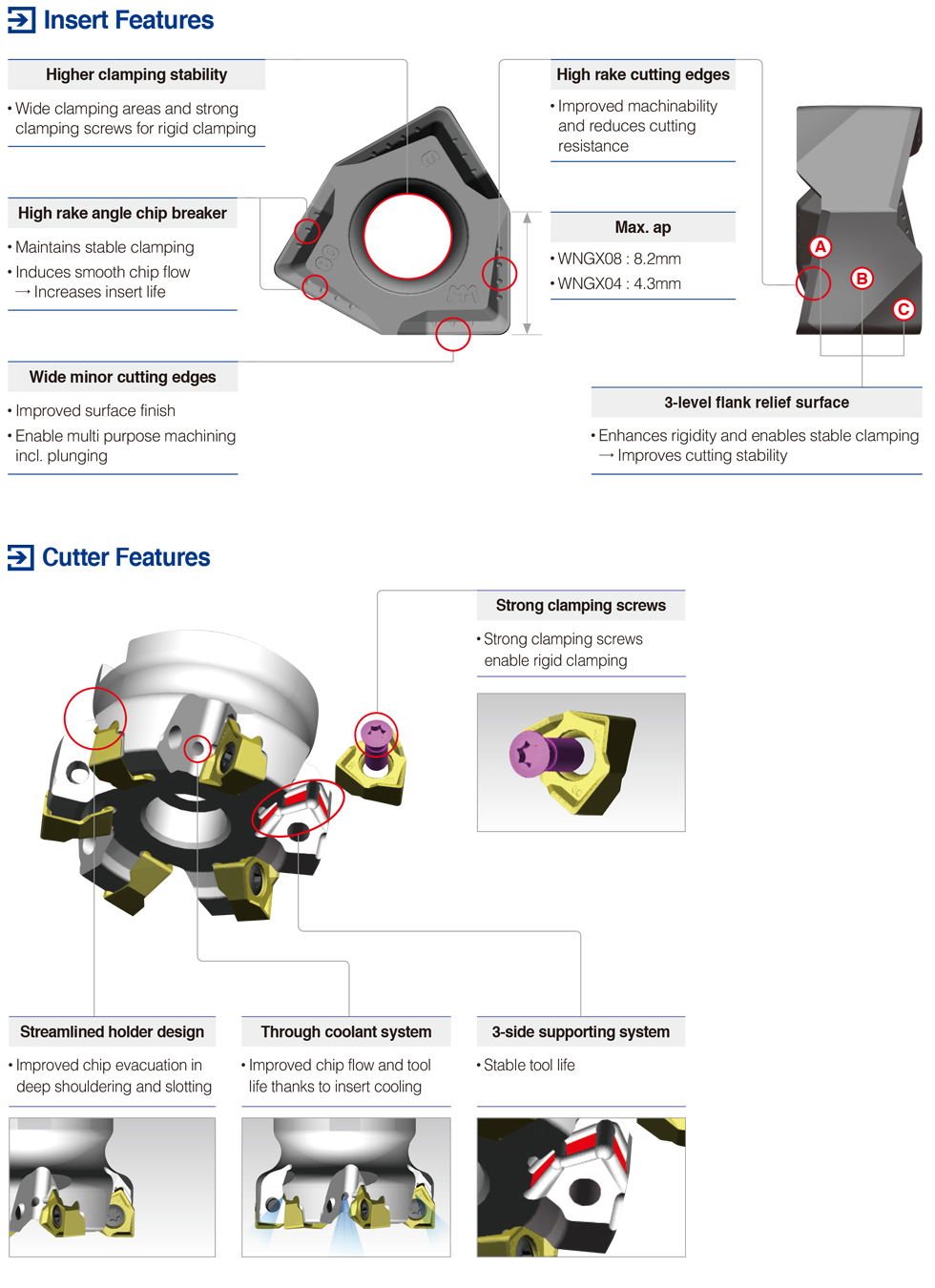

• Superior clamping stability

– Powerful clamping thanks to strong clamping screws and 3-side flank supporting system

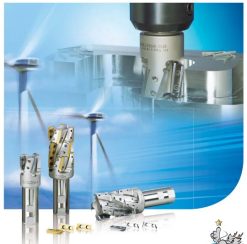

RM6

Mold making companies are required to keep up with the demands of the accelerated development of Industrial structures.

RM6, KORLOY’s new Rich Mill Series for shouldering responds to these demands by employing double-sided inserts with six perpendicular corners to achieve cost efficiency. It features strong clamping screws, 3-side supporting system, and wide clamping areas which enable powerful clamping force. This facilitates stable machining at high speed and feed, and delivers higher productivity.

Wide minor cutting edges and optimized multi-stepped relief surfaces of the RM6 provide exceptional bottom surface finish. The RM6 achieves perpendicularity and improved flank surface finish. The chip breaker design high rake and high helix angle were applied to the inserts for stable cutting performance in hard-to-cut materials or high hardened workpieces, achieving an increase in tool life.

KORLOY’s RM6 is one of the most advanced shouldering solutions available to meet the demand of the mold making market today.

Advantages

• Superior clamping stability

– Minimizes vibrations during operations

– Enables soft cutting performance with little noise

• Increased productivity thanks to high speed and feed capabilities

– Sharp chip breaker enables soft cutting performance

– Multi-stepped relief angles maximize rigidity

• High quality surface finish

– High precision tools make excellent perpendicularity

– Even flank surface finish

– Exceptional bottom surface finish

• Streamlined holder design

– Facilitates chip evacuation in slopping or deep shouldering