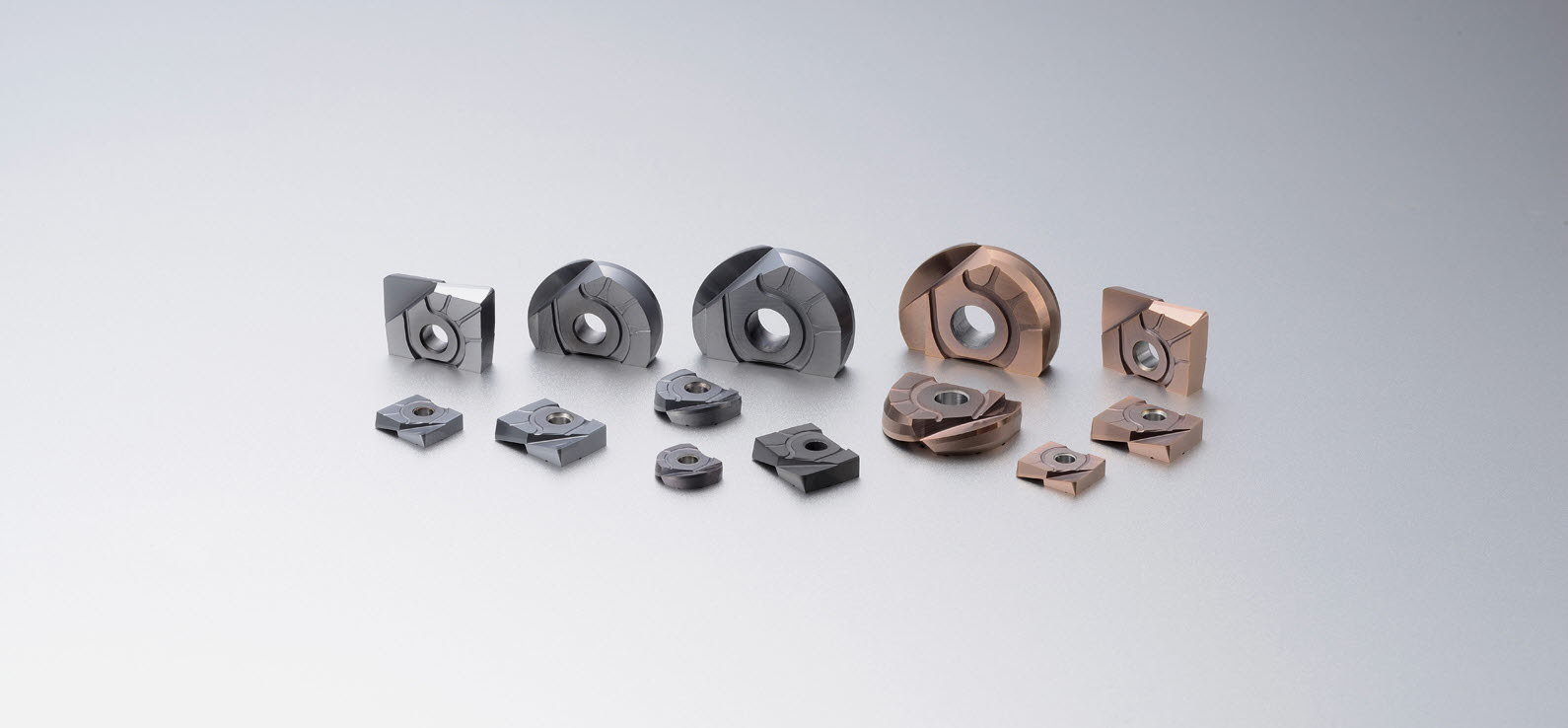

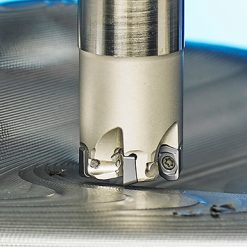

– Outstanding increase of wear resistance through optimized grade per workpiece

• KF / KH Chip Breaker

– Increased strength and design of cutting edges through optimized blade geometries per workpiece

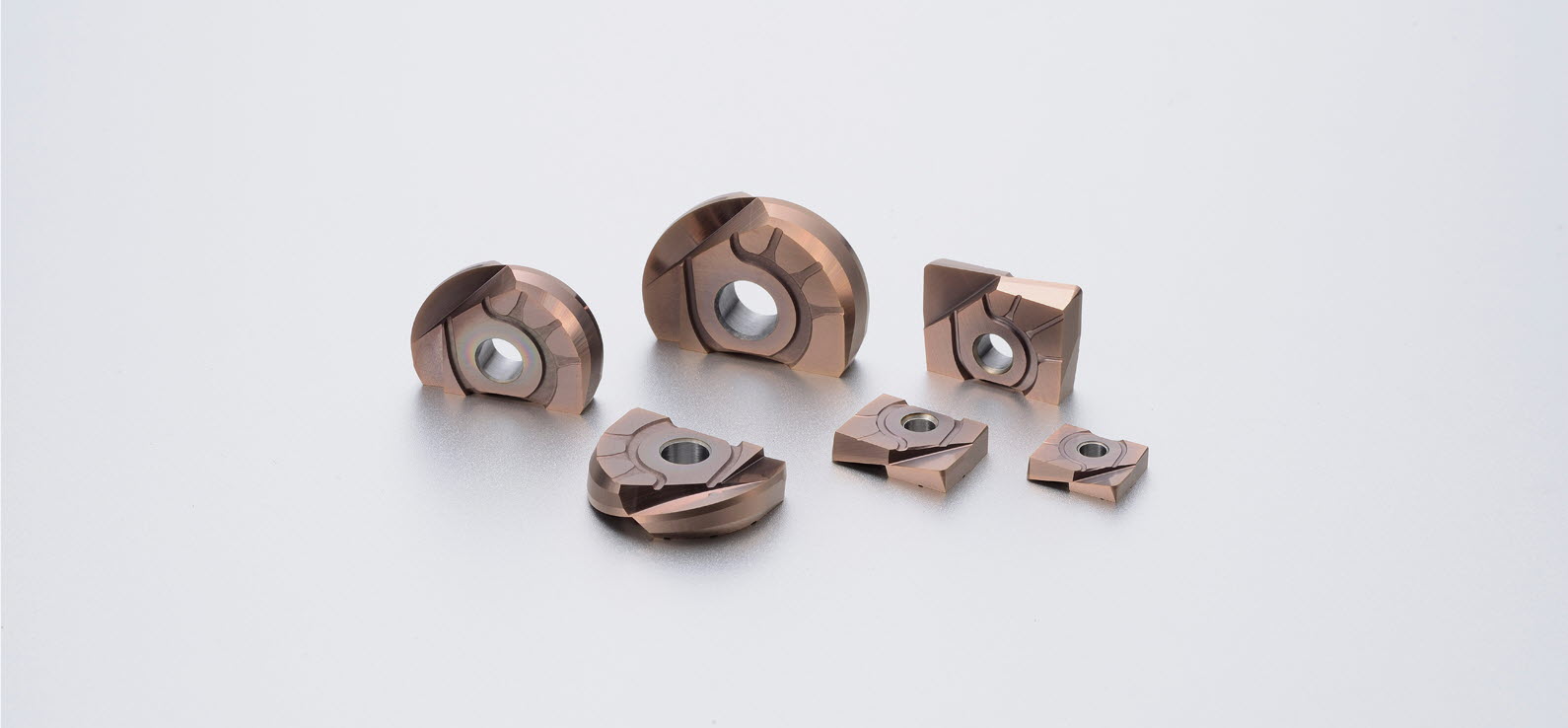

PC2005 · PC2010 · PC2015

PC2005 Tool steel or high hardness steel after heat treatment has very high hardness that causes severe wear on relief surface of cutting edges during cutting actions, as well as chipping due to heavy cutting loads. In order to prevent these problems, we progressively improved wear resistance and chipping resistance of the substrate by applying ultra fine raw materials to PC2005.

PC2010 In cutting conditions when cutting fluid is applied, thermal cracks occur on tool’s surface due to repetitive thermal impact. To avoid thermal cracks, we applied a heat shield coating to PC2010. In addition, it was optimized for wet machining of pre hardened steel by using ultra fine raw materials and high binder on substrate and thus increasing stability.

PC2015 When machining carbon steel and mild steel, wear that looks like bites on tool’s relief surface is caused by viscosity between tools and workpieces. PC2015 guarantees excellent tool life and machining stability with its characteristics of the high toughness substrate and the welding resistant coating with low reactivity to workpieces.

Advantages

• Perfect harmony between grades and chip breakers

– Increased tool life and prevention against unexpected breakage

• Increase wear resistance and breakage prevention

– Possible to various cutting conditions

• Available for all kinds of workpieces including high hardness steel, tool steel, pre hardened steel, carbon steel, cast iron, etc