Increased wear resistance

– H igh hardness and high purity diamond coating for excellent wear resistance

• Improved surface finish

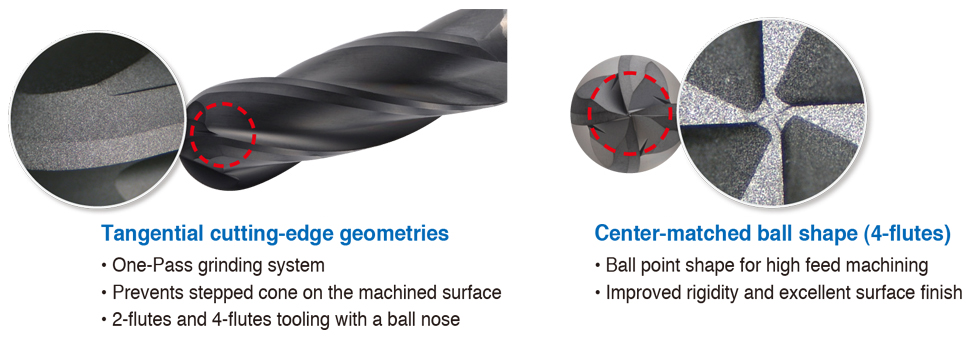

– Tangential cutting edge geometries for excellent surface finish

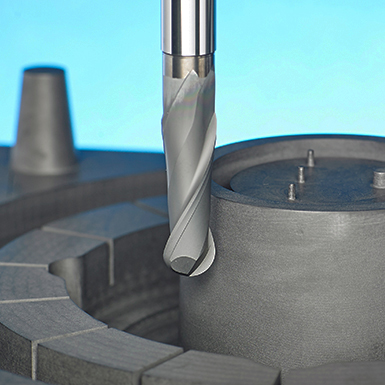

D Endmill

Cutting tools made for graphite tend to have poor tool life during machining. Friction between graphite molecules and the relief surface of endmill cause early tool wear, and its high hardness is also responsible for the possible flaking of the diamond coating.

It is therefore important to develop a diamond coating that has high hardness and good adherence to the substrate. In return, this will reduce the occurrences of tool wear and flaking, resulting in an increased tool life.

The ND3000 is a new diamond coated grade with high hardness and high purity sp³ structure that improves wear resistance. It also offers higher resistance to flaking since it holds the coating and the substrate tightly together.

The D Endmill provides precise and sharp cutting performance thanks to optimized tangential cutting edge design. This versatile tool excels in graphite machining under complex conditions.

Advantages

• Excellent surface finish

– Tangential cutting edge geometries

• Increased tool life

– High hardness diamond coating applied

• Excellent cutting performance

– Optimal blade design