APPLICATION

Application: Takes the place of reaming, erosion or milling — Changes in the work process are no longer a problem with formbore

Machine type: formbore system tools can be used on machining centres, milling, turning and special purpose machines.

FEATURES

- no synchronous coordination to the machine necessary

- independently of the machining spindle

- blind holes without residual chips

ADVANTAGES

- enduring dimensional accuracy

- almost wear and maintenance-free

- considerable reduction of working time

- designed for many different profile shapes and sizes

DESCRIPTION / QUALITIES

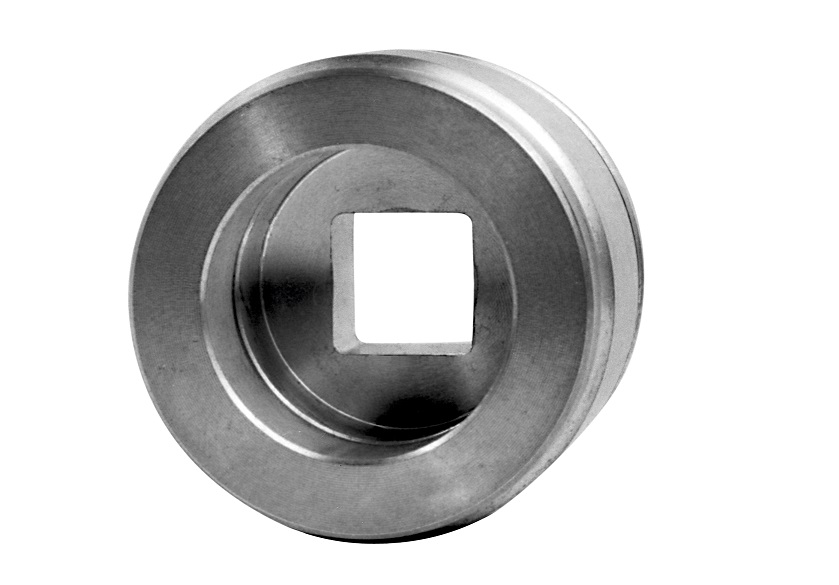

As flexible and independent as convincing: For the first time you can produce a high variety of inner and outer profiles with the highest possible precision by means of simple drilling and turning processes on normal machining centres. formbore system tools are designed for different profiles and profile sizes. It is possible to make changes to the working process, for example to separate reaming, erosion or milling.

Formbore system tools reduce the working time considerably in comparison to the processes currently being used. Further advantages are blind holes without residual chips and the constant accuracy due to the correction of the cutter wear. The torque support and the modular tool holders are identical to the ones used on the Bilz GNCK / GNCN tapping attachments.

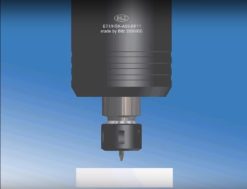

DESIGN AND MODE OF OPERATION OF THE FORMBORE SYSTEM TOOLS:

Formbore system tools consist of two components: drive shaft and drill chuck. The rotating drive shaft is located in the case. The torque driven control determines the movement sequence of the drill chuck. The deflection of the blade is by means of entirely rolling elements. formbore system tools therefore operate practically wearand maintenance-free and make machining of most materials up to 900 N/mm2 strength possible.

For inside processing, a formbore is initially machined up to a maximum of 0,5 mm diameter smaller than the spanner size (SQ). The actual form drilling operation is carried out in a single process with profile adjusted speed and feed appropriate to the material being machined. The formbore system tool is a system for a practical versatility, flexibility and time and cost saving in daily work. Let us know your processing requirements. You will receive our specific tool recommendation and our offer will convince you of the advantages of the new formbore development.