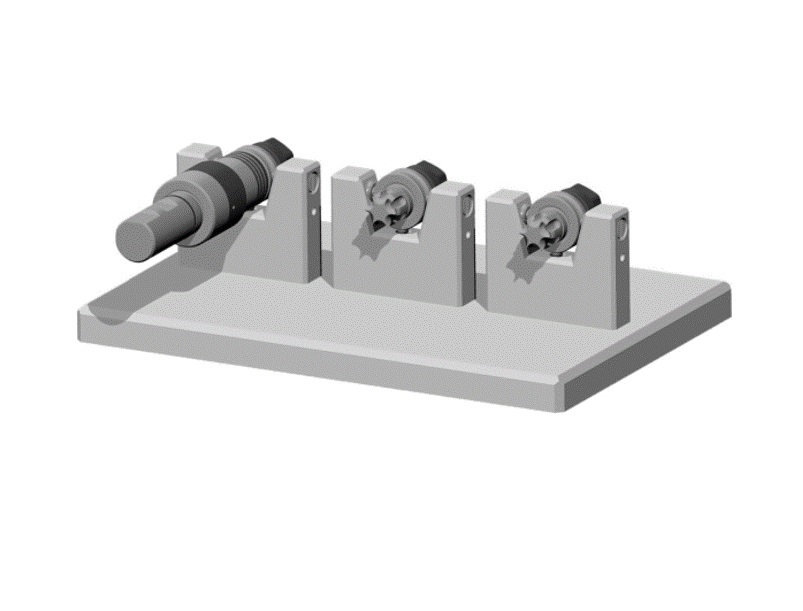

APPLICATION

Application: Deburring, brushing, cleaning, polishing, grinding, drilling and rubbing operations

Machine type: Industrial robots

FEATURES

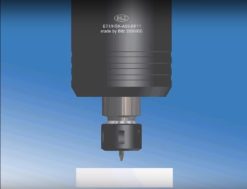

- Spindle holder: DIN 1835 form B and E; all other holders (e. g. HSK) possible

- Tool holder: Collet size ER16 or according to customers‘ specification

- Floating function possible

- Central coolant flow possible

ADVANTAGES

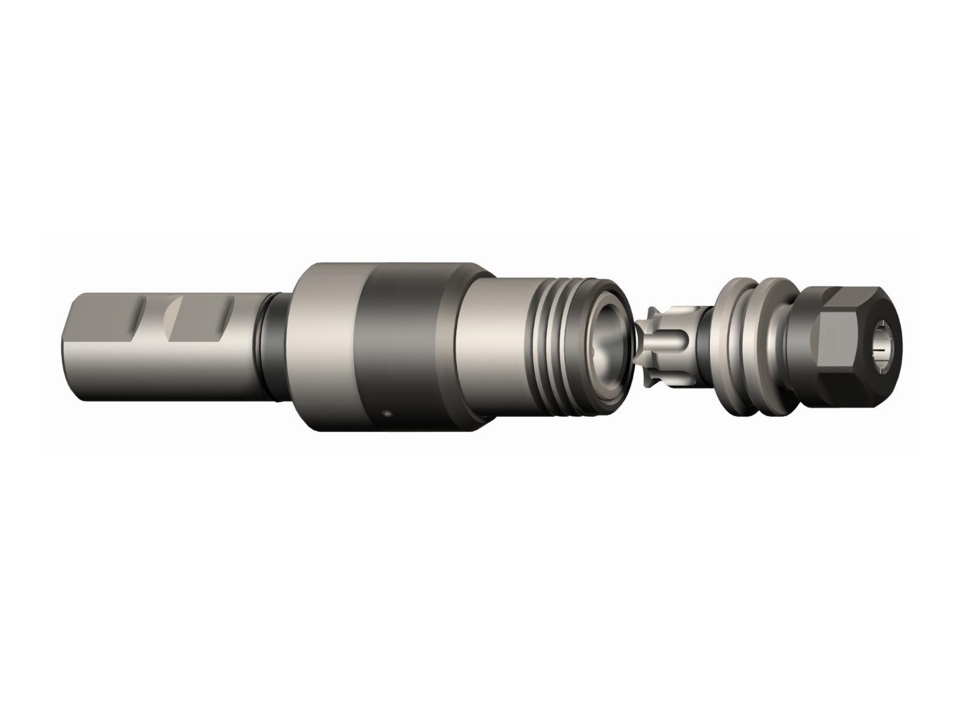

- Makes clutching and declutching of processing tools possible

- Independent of the rotational position of the spindle

- Coupling can be effected via a tension or also via a shift sleeves

- Better sealing compared to actual quick-change systems

DESCRIPTION / FEATURES

Automated and partly-automated processes become more and more important due to the increasing industrialisation. The result is an augmenting number of robot systems in our productions. Beside the conventional loading and unloading of machining centres these robot systems take over tasks such as deburring and grinding in the downtimes. But also, in the production of light-weight components (aluminium, plastic, fiber composites, …) and the additive production, these systems are more and more in use – also for drilling, rubbing or tapping processing.

All these processes have in common that the driven spindle normally does not allow a positional orientation. The tool change turns out to be a problem.

Made in Germany

All floating holders are manufactured at the Ostfildern-Nellingen site and at the Betra plant near Horb.

Original Bilz

Quality – We provide all products with a custom product number. Because we always play it safe – from purchasing to delivery.